Beverage Container Coding:

Ensuring Quality, Safety, and Traceability

Beverage container coding is a crucial component of modern beverage production, ensuring quality, safety, and efficiency across the supply chain. By leveraging the latest coding technologies and best practices, manufacturers can enhance consumer trust, comply with regulations, and optimise operational performance.

Choosing the right solution:

Our robust, versatile and high-performance solutions for industrial coding on beverage containers are:

Hitachi LM-C331S: Power & Wavelength at 30 W 10.6 μm.

Hitachi LM-C11P: Power & Wavelength at 10 W 10.6 μm.

Hitachi UX2: The UX2 exemplifies this versatility, providing crisp, high-resolution printing on virtually any surface.

The importance of Coding

Beverage container coding is essential for multiple reasons:

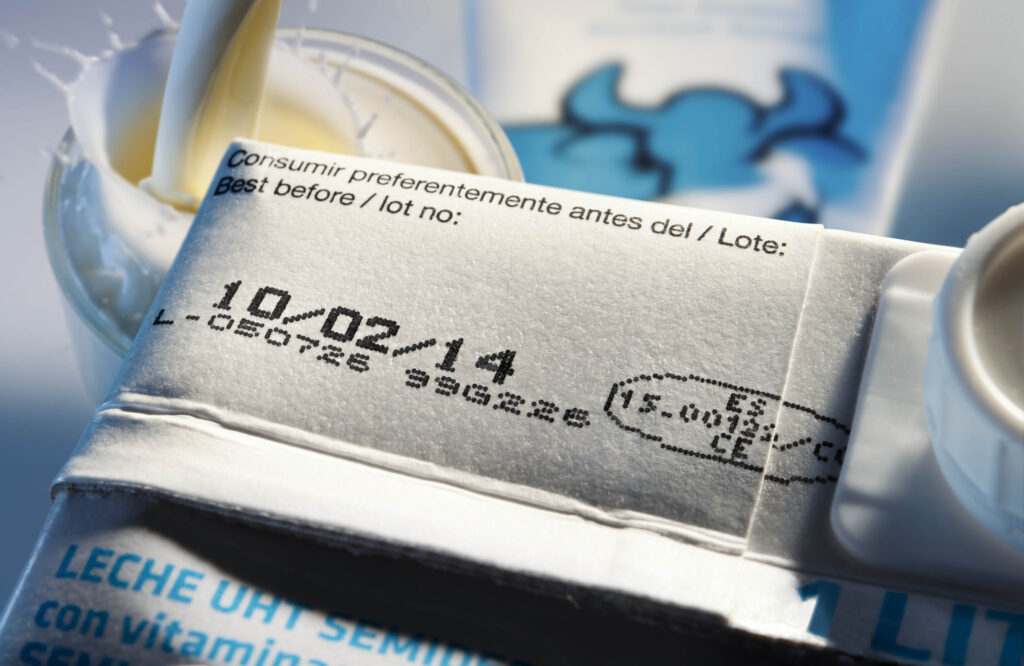

Product Traceability: Enables manufacturers to trace a product back to its source in case of recalls or quality control issues.

Consumer Safety: Provides crucial information like expiry dates to ensure safe consumption.

Regulatory Compliance: Meets industry standards and government regulations for food and beverage labeling.

Brand Protection: Prevents counterfeiting and ensures authenticity.

Supply Chain Efficiency: Facilitates inventory management and logistics tracking.

Types of Beverage technology:

Different coding technologies are used based on packaging materials and industry needs:

Inkjet Printing: Ideal for high-speed production lines, inkjet printers apply alphanumeric codes and barcodes on bottles and cans.

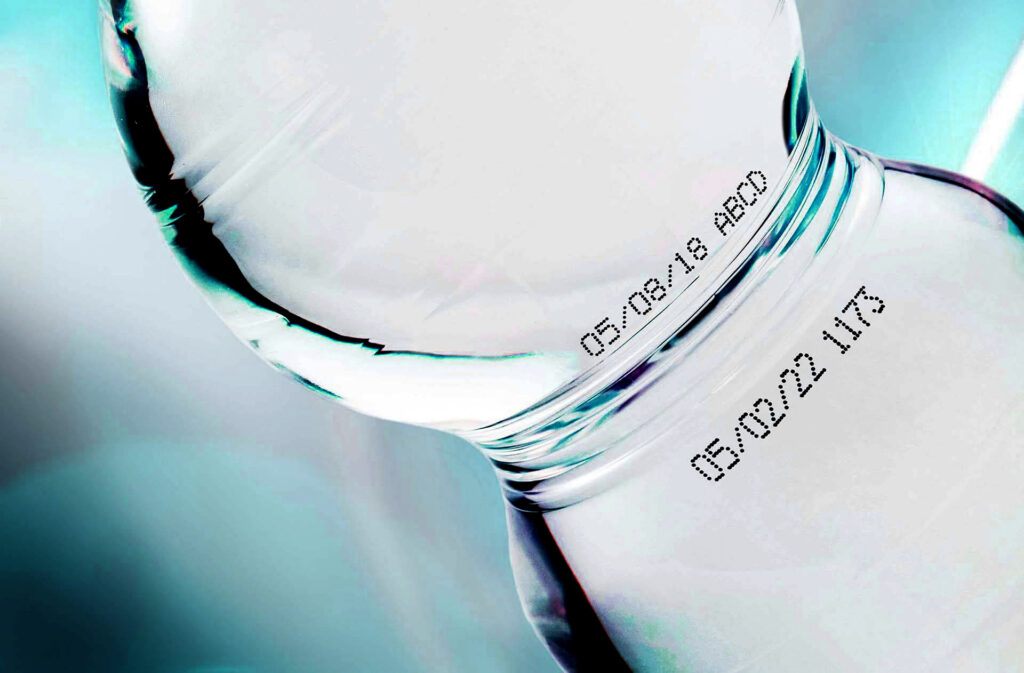

Laser Marking: Uses laser technology to etch permanent codes onto glass, metal, or plastic surfaces.

The Hitachi Laser is capable of printing up to 600 cps (characters per second) on a variety of objects which are moving at high-speed on production lines.