Visy Vision Systems for primary and secondary product inspections

Welcome to the future of quality assurance. Vision inspection harnesses the power of vision and advanced image analysis capability. Product defects can be detected at high speed and rejected from production in real time ensuring the best possible production quality.

The Visy Vision System range:

A robust, versatile, high-performance custom designed inspection system designed for your requirements.

Primary Product Inspections: Individual Unit Inspection.

Secondary Product Inspections: Outer Carton Inspection.

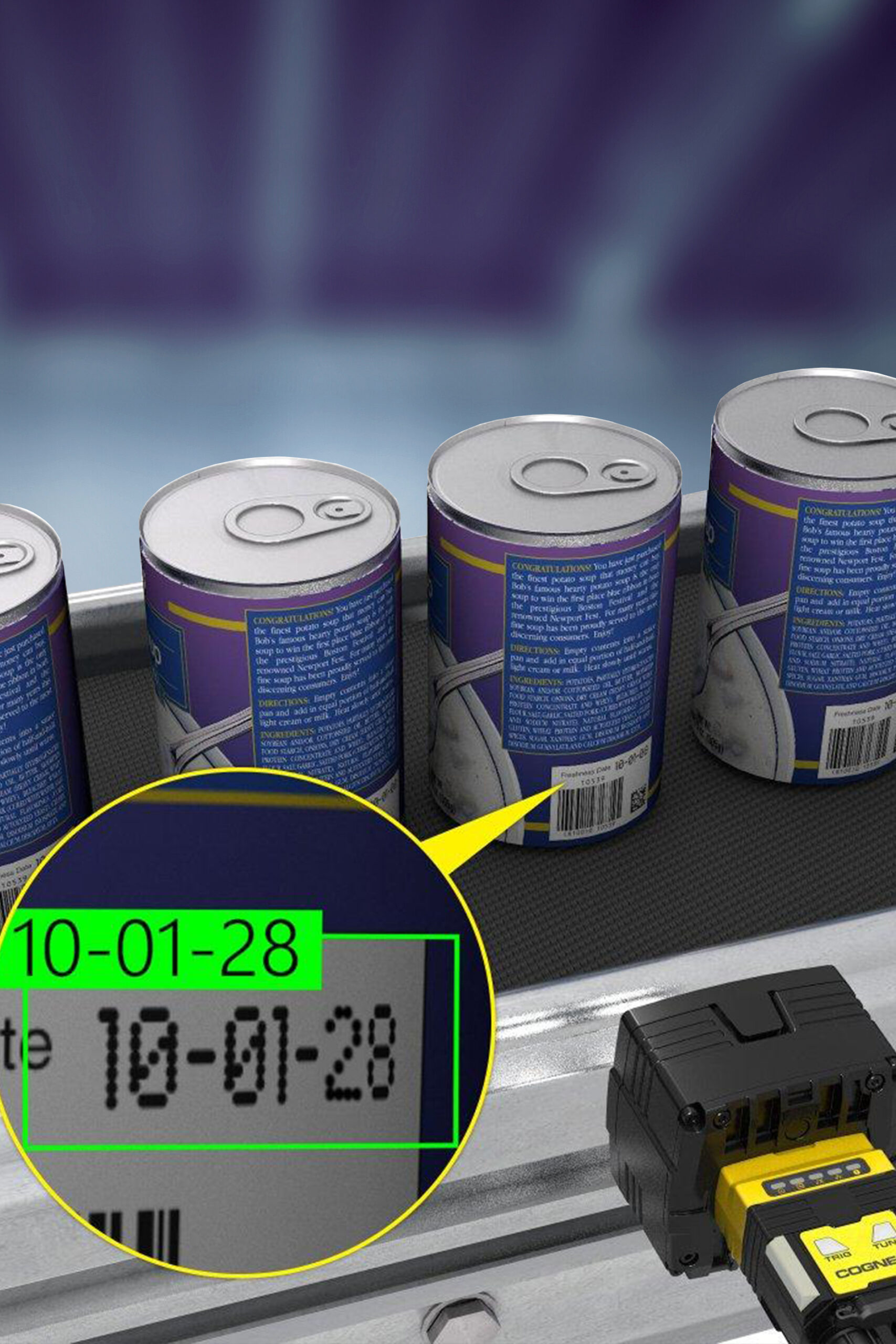

Optical Character Reading Inspection: Vision Sensor and VLR application station

Meeting the highest of industry standards by analysing your products for defects or imperfections.

Vision Applications

Secondary Packaging – Vision Inspection

Vision systems check for presence and OCR of human readable text along with 1D and 2D Barcodes.

Primary Packaging - Defect Detection

OCR human readable date code codes for presence and quality, Check labels for application quality and verification.

Caps, Label and Fill Level Detection

Filled container checks to verify fill level, closure and label application are free from defects.