Hitachi Software Suite

Powering Innovation with Advanced Technology

Hitachi Coding Software Suite is a software solution that enables users to remotely design messages and monitor Hitachi inkjet printers. In addition, the HCSS enables centralised management of messages, which reduces operator errors , improves equipment visibility, and increase plant productivity.

Hitachi Coding Software Suite capabilities:

– Edit messages via an intuitive WYSIWYG user interface

– Manage print messages from central database

– Monitor real-time status for multiple printers

– Connect via multiple devices (PC, laptop, tablet, phone)

Software Suite features:

As the core of Hitachi‘s Coding & Marking Solutions, the Coding Software Suite (HCSS) from Hitachi has a client/server architecture with flexible web browser based user interface for operators to design labels, control, manage and monitor coding marking devices such as printers and vision system, access the printer dashboards and configure and manage automated printing applications dynamically.

Client Server Web Based

Install once, access anywhere via web browser on PC, tablet or smartphone.

Message Designer

Powerful WYSIWYG (what you see is what you get) message designer for Hitachi Continuous Inkjet printers.

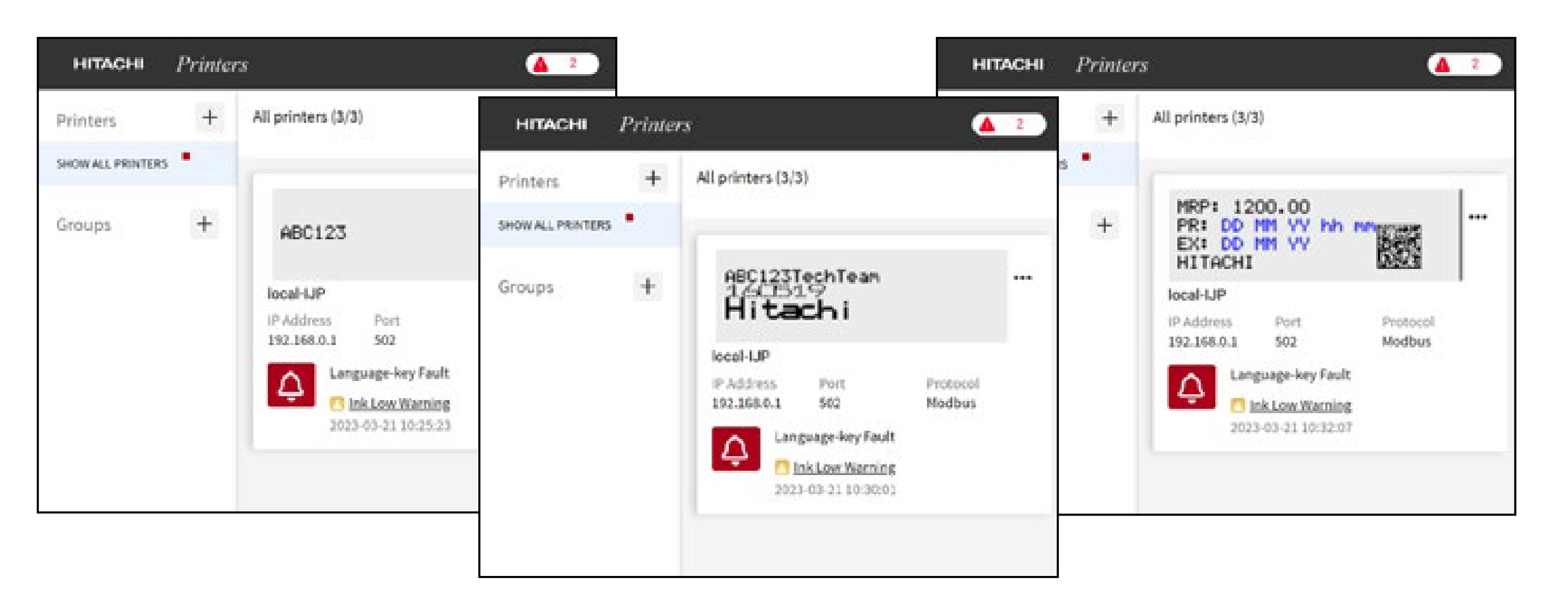

Device Management

Individual printers, printer groups and/or vision system (MC20S) can be managed as the target devices and the statuses of these networked devices can be viewed in one aggregated view or individually in detail. Message preview and Basic device remote operations available for IJPs. Basic MC20S remote operations are also available.

Printing Automation

Powerful and configurable platform to fetch data from local or remote customer data source and dynamically populate labels to meet various application requirements.

Dashboard

All critical printer status and data can be viewed from predefined or customised dashboards to remotely monitor and manage printers on production lines.

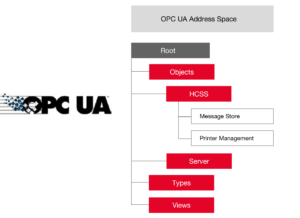

OPC-UA Connect

Flexible OPC-UA server application, provides powerful business logics and bridge to connect customers’ MES and ERP system to network printers.

End to End Coding Automation.

Printing Automation

User-friendly HMI allows users to manage:

- Message style

– Individual

– Free layout - Print format

– Set number of lines

– Add/remove columns

– Bold, Dot Matrix, Inter-Character and line spaces - Print specification

– Character height

– Ink drop use

– Character width and orientation

– Print start delay

– Product speed matching

– Speed and fine control compensation

– Encoder pulse rate division factor

– Line speed

– Print distance (Head to target)

– Print target width

– Actual print width intervals

– Target sensor timer and filter

– Ink drop charge rule - Calendar and count condition

Create the message with diverse contents, e.g:

- Alphanumeric

- Calendar

- Counter

- Time counter

- Logo (*bmp) elements

- GS1 compliant 1D and 2D codes

Powerful message management, persistence and control can transfer the created message between the file system/database and the printer or printer groups.

WYSIWYG message preview and listing.

Device Management

- Printer registration management – add/remove printers or printer groups

- Printer grouping management – create and edit printer group

- Send and print message to group printers simultaneously

- Printer message previewing

- Remote operation (start, shutdown, ready, standby, fault clear, Online/Offline)

- Vision system registration and statues monitoring.

- Basic vision system remote operation

- Marking Check job management.

Monitor with real time status of printers or printer groups:

- Ink operating time

- Ink (remaining) level*

- Makeup (remaining) level**

- Ink pressure

- Ink/Makeup replacement warning

- Print count

- Maintenance and environment information

- Dynamic printer alarm management Individual and grouped printers overview on a single screen. Preview of data source & message layout.

* available from UX-D Series only

** UX-B and UX-D860W are not supported

Printing Automation

- CSV, Text or Databases data source (SQL server, PostgreSQL, MySQL) connections.

- IJP Protocols support for Modbus (TCP) or RS-232C (Tunneling)

- Data preview

- User friendly mapping between label items and data source fields

- Dynamic Print Automation Jobs

- Preview of data source and message layout

- Individual or group target printers setting

- Automatic print speed

- Repeat printing function

- Multiple print job creation

- Print job status monitor and reporting

OPC-UA Connect

- Connect with HCSS using OPC-UA Protocol

- List IJPs

- Read IJP Parameters

- Operations can be performed e.g:

– Set/Reset Print Count

– Get Alarm Count

– Get Alarm History

– List Messages

– Send Message to Printer

– Send Message to Group

– Update Message

– Read Current Message

– Built-in customer business logics

Dashboard

Display detailed status overview of all connected printers using a collection of different widget types

- Various dashboards to display available printer status data and remaining operation time for parts which require regular maintenance and replacement

- Dashboards can be customized by resizing, replacing, and repositioning widgets

- Switch between Live and Historical mode

- Selection date-range (Date/Time) for filtering data

- Reported parameters include:

– Ink/Make-up levels (UX Series only) Ink viscosity, Ink pressure, Ink use time

– Ink/Make-up consumption

– Print count, cumulative operating time, ambient temperature

– Deflection voltage, Excitation V-Ref, Excitation frequency

– Filters, Valves, Pump remaining usage time

– Operation, Warning status

– Printer Type, Serial Number

– Basic OEE