Carton Barcode Labelling: ensuring accuracy and efficiency in logistics

Carton barcode labelling is a crucial process in supply chain management, ensuring seamless tracking, identification, and inventory control. By applying barcode labels to cartons, businesses can automate data capture, reduce human errors, and improve operational efficiency.

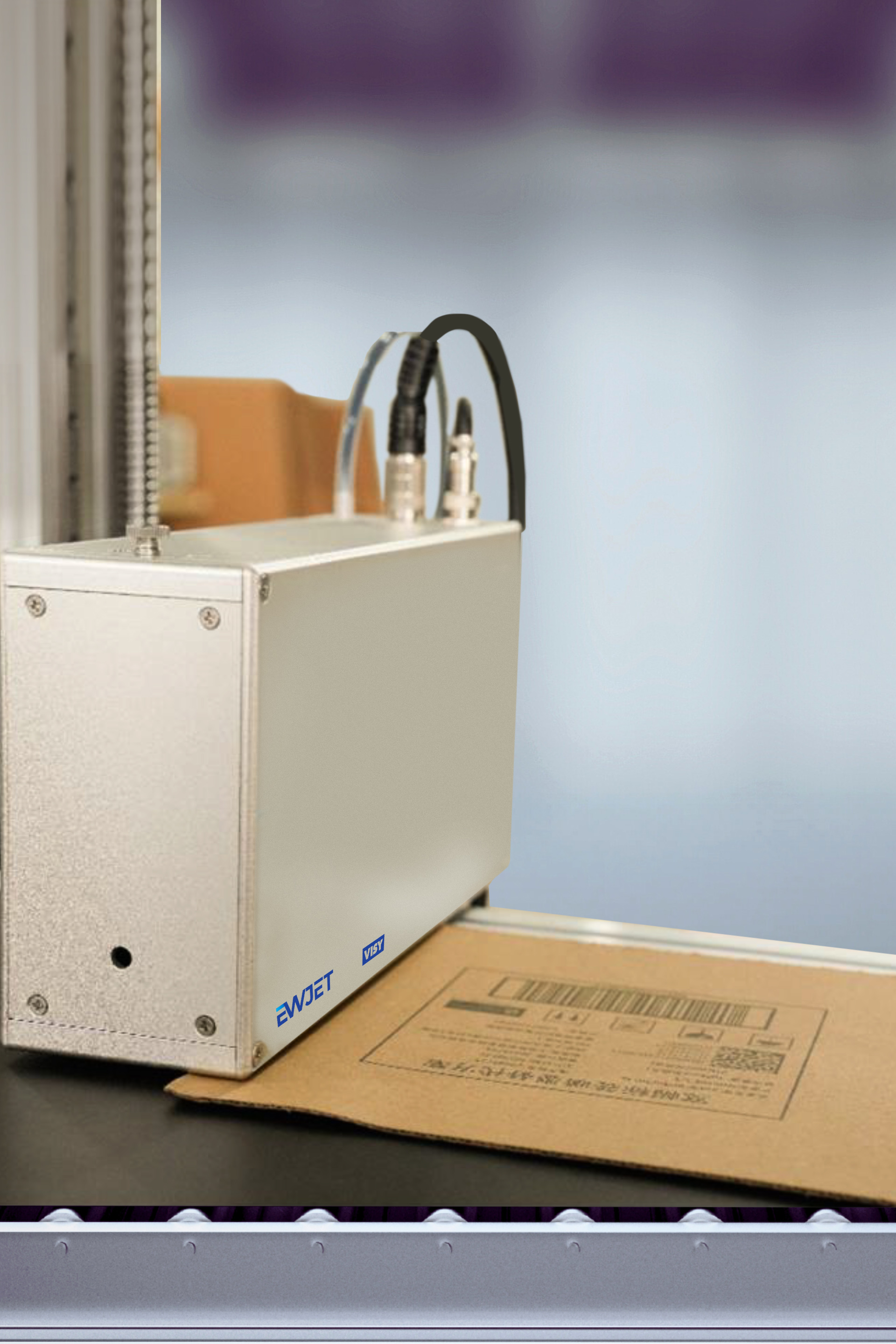

Our carton coding and labelling solutions are designed to fit seamlessly into your business operations. With user-friendly features and rapid implementation, ensuring accurate and compliant carton labels has never been easier. We offer a range of inkjet coding solutions to print essential product information, branding details, 2D codes and more. Our solutions can be designed to integrate directly into your production line to enhance efficiency across the board.

Choosing the right solution:

HM Linerfree: A Print & Apply solution for box and package labelling that doesn’t use backing paper/release liner.

CAB Hermes Linerfree: A cutting-edge labelling solution designed for industrial environments where precision, speed, and reliability are critical.

TL DUO: An efficient carton sealing and labelling system based on top and bottom drive carton transfer.

CAJO Technology: Their patented laser technology enables precise, durable, and eco-friendly markings on a wide range of materials, including metals, plastics, and coated surfaces, without the need for additives or chemicals.

The benefits of Carton Barcode Labelling

Enhanced Inventory Management. Barcode labels allow for real-time tracking of inventory, reducing the chances of misplaced or lost items. They help streamline stock management and facilitate accurate stock audits.

Improved Accuracy and Reduced Errors. Manual data entry is prone to errors, which can lead to costly mistakes in inventory and shipping. Barcode scanning eliminates these errors, ensuring precise information capture.

Efficient Order Processing. With barcode-labelled cartons, businesses can process orders faster, improving picking, packing, and shipping accuracy. This leads to improved customer satisfaction and reduced returns.

Seamless Supply Chain Integration. Carton barcodes can integrate with warehouse management systems, enterprise resource planning software, and logistics platforms, ensuring smooth data flow across different operations.

Regulatory Compliance. Many industries require standardised barcode labelling to comply with shipping and regulatory guidelines. Using compliant barcode labels helps businesses meet industry standards and avoid penalties.

Types of Carton Barcode Labels

1D Barcodes (Linear Barcodes): Commonly used for general tracking and inventory purposes.

2D Barcodes (QR Codes, Data Matrix): Store more information and are often used in advanced tracking systems.